With the popularity of the LEED rating system and the stringent energy efficiency requirements of some building codes, developers, owners and designers are paying close attention to the energy performance of their new buildings. BIM models created by architects and engineers during design are being used by contractors during construction and then passed along to the owner and operator for use during the life of the building.Īnother major change in the industry recently is the focus on energy modelling. Many architects, engineers, contractors, owners and operators are starting to look beyond 3D BIM toward 4D (time), 5D (cost) and even 6D (life-cycle management). For example the model will know if the user is trying to draw a length of ductwork through a structural column, unlike a 2D CAD drawing which will not make this distinction.Īs technology changes, so does the idea of BIM. All this work must be done within a breakneck schedule, at the lowest possible life-cycle cost, with the lowest possible environmental footprint.Ī big reason why 3D BIM has been so widely adopted is that it has the potential to reduce coordination time between disciplines. From HVAC, plumbing and fire protection to power, lighting and controls, it is the role of the MEP engineer to make these systems work within the overall context of structure, architecture and site.įurthermore, the expectations for new construction in this day and age are very high. Engineers, designers and energy modellers work together behind the scenes to provide all the sophisticated systems that we expect to find in the built environment. Within an MEP engineering office many specialized professionals are involved in putting forward an efficient, coordinated and cost-effective design. High performance buildings are complex systems. And the many tools that do exist often have trouble getting along. There is no single tool that can do everything well.

#IES VE REVIT PLUG IN SOFTWARE#

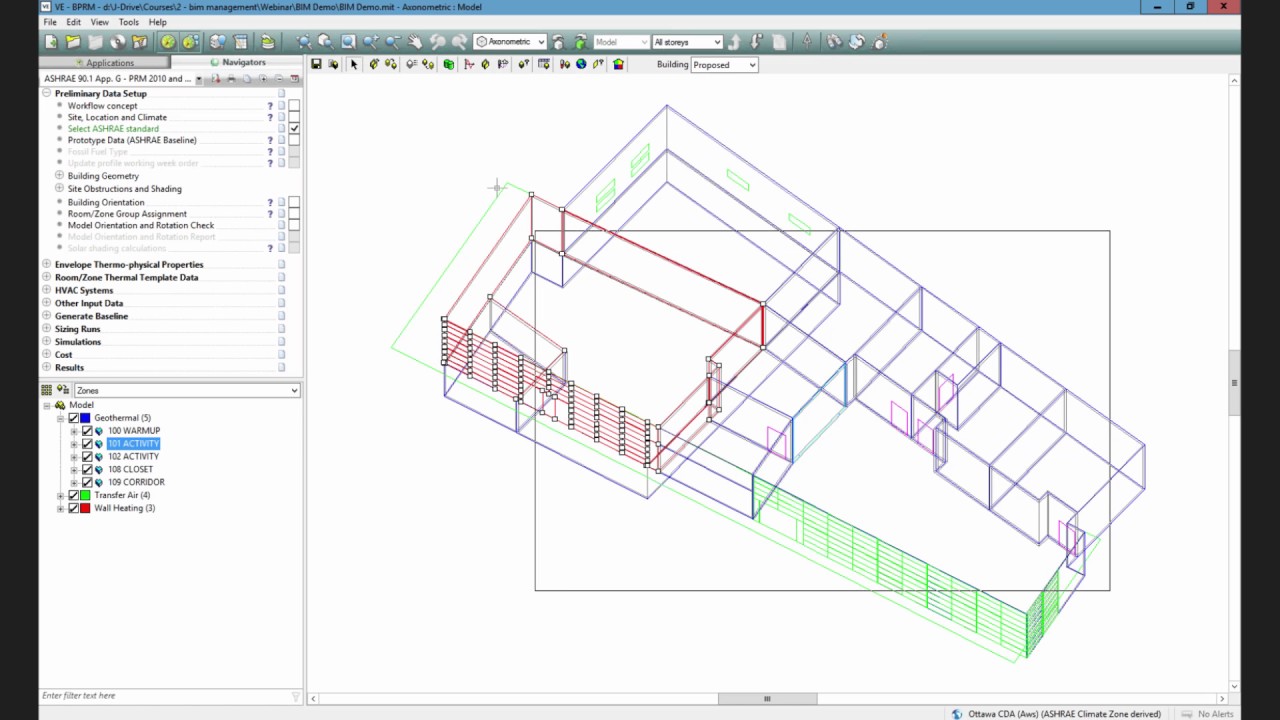

Three different models developed by three different departments for three different tasks on a single building.Īlthough the software tools have improved dramatically, there is still a disconnect between expectations and reality. Three different tools for three different tasks: HAP or TRACE for load calculations, Revit or AutoCAD for design/production, eQUEST or IES for energy modelling.

Even still, this triplication of work is common practice in many mechanical-electrical-plumbing (MEP) engineering offices. Why do a job once when you can do it three times? If you are only being paid to do the job once then the answer should be obvious.

0 kommentar(er)

0 kommentar(er)